andrew murray consulting

food process and project engineers

Comment

Ecological Thermodynamics -

What is it and why is it vital to the future of the food industry.

G. Tyler Miller, an American Chemist calculated that -

Three

hundred trout are needed to support one man for a year. The trout, in

turn, must consume 90,000 frogs, which must consume 27 million

grasshoppers that live off 1,000 tons of grass.

Does this mean

that if trout was the only available food to man one man would require

the input of 1000 tons of grass every year? And what has it to do with

Thermodynamics?

What is it?

Let us consider a simple idealistic ecological system containing only grass, rabbits and foxes. We might want to know:

* how efficient the grass is at converting inorganic matter into rabbit food

* how efficient is the rabbits' production of fox food

* how efficient are the foxes in producing biomass and energy from rabbits.

To

answer the questions meaningfully and a host of similar ones we need to

understand the basics of the thermodynamics of the systems.

The laws of thermodynamics can be adapted for simplicity to state the following

All

work and growth requires energy and energy cannot be created or

destroyed; (First law). That is, without photosynthesis and radiation

from the sun there will be no grass, no rabbits and no foxes.

Increased

order (growth, complexity) in one part of a system entails increased

disorder (entropy) in another part (Second law) An increase in fox

order implies an increase in rabbit disorder.

Mass cycles

through an eco-system. Thus in the system we considered above the mass

goes from inorganic matter to grass to rabbit to fox and via

decomposition and microbial action back to inorganic matter. We need to

add the decomposers (bacteria) to our hypothetical system. The

relatively short times in our planet's history that the decomposers

have been inactive have resulted in the deposits of fossil fuels which

we are now depleting.

In contrast to mass, energy flows through

the system. It enters the system through the sun’s heat and light

in photosynthesis and is eventually dissipated in heat generated

through movement, metabolism, and decomposition and it is then radiated

out through the atmosphere to space.

This is the basic

principle of ecological thermodynamics and is true for the system

planet earth - materials cycle in ecosystems, energy flows through

them. The mass of the planet is fixed. Radiant energy from the

sun continually reaches us and energy is continually being dissipated

from the planet into space.

Ecosystems are far more

complex than the simple grass-rabbit-fox scenario and one needs to

consider food webs rather than food chains.

Biomass can only be produced by plants and certain bacteria. We designate these autotrophs or primary producers.

Herbivores

convert the plant material into energy and biomass. Carnivores in

turn use the energy and mass provided by the herbivores.

Once again it is not quite so simple. There are omnivores and

there are higher levels of carnivores that prey on other carnivores.

Each

step is designated a trophic level. Thus plants are the lowest

trophic level, herbivores (eg grasshoppers) next and levels of

carnivores (frogs, trout) and omnivores (humans) higher up

the food chain or food web. Finally bacteria take the waste from

all these process and convert it back into inorganic matter.

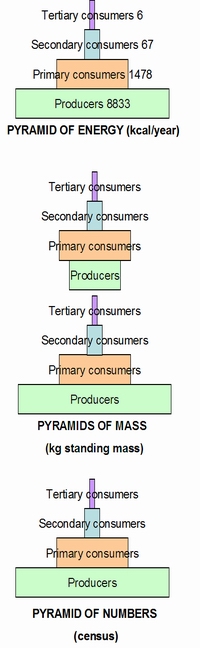

In

terms of the second law every conversion is characterised by a

reduction in energy. It is possible to draw an energy pyramid which

shows the energy produced by each trophic level. It is also possible to

draw a pyramid of mass and a pyramid of numbers.

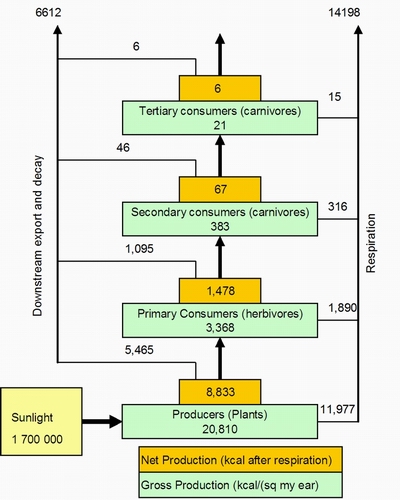

The American

environmentalist, Howard T Odum studied an ecosystem at Silver Springs,

Florida. As a part of his study he constructed an energy flow

diagram which gave the flow of energy per square metre per year.

This has been simplified to an energy pyramid. Alongside the

energy pyramid it is possible to construct pyramids of number, the

census at a given time of the populations and a pyramid of mass, the

standing mass of the system. The standing mass pyramids and the numbers

pyramids may be inverted indicating that the lower trophic levels

replenish more quickly than the level above. This is similar to the

food in your larder at a given time being less than you require for the

year. You buy more when needed. The pyramid of energy

cannot in terms of the first law be inverted.

Similar

research has been conducted for other systems and indeed energy

diagrams have be produced for the analysis of our total global

footprint.

And why does the industry need to take note

The

analysis of the energy flows can become rather complex and indeed

particularly so when one considers human requirements and

expectations. An analysis of the planet might consider energy and

entropy in transfers between the atmosphere, lithosphere, hydrosphere,

biosphere and technosphere as well as within each of these

divisions. A few of the important results from many such

analysis are the following:

There is a limit to the number of trophic levels that can be sustained in any food chain.

The

efficiency of each level may be considered as being about 10%. Some may

be as low as 1% and some reach as high as 15%. Generally animal

husbandry will provide for more efficient systems.

The

greenhouse gas emissions from the livestock industry is between 18% and

51% of the total global emissions (depending on how one does the

calculations). Thus, they possibly exceed the emissions from

power plants world wide. This information has led to a

trend of eco-vegetarianism.

Humans presently appropriate

40% of all terrestrial net prime production (NPP). The bulk of

this is for food. It does not leave much space for

bio-energy or to alleviate poverty without drastic changes to

technology, reduction of waste and reduction in expectations.

Responsible

use of biomass and bio-energy in the future is central to human

survival. Technically, this is in the hands of the agricultural

and food industries. A holistic approach will require understanding of

how ecosystems use energy.

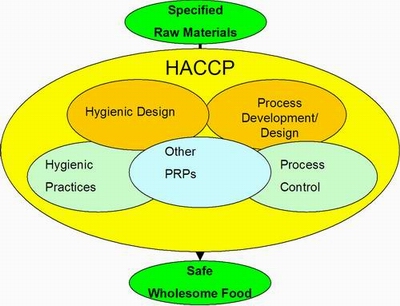

Hygienic design, PRPs and HACCP

The object of a food process operation is to produce safe wholesome food from specified raw materials.

This requires the design of a suitable process to kill or control relevant microorganisms together with a suitable process control system.

Further it requires the application of hygienic design incorporating:

• factory siting

and construction

• design of the

building structure

• selection of

surface finishesCape Town

• segregation of

work areas to control hazards

• flow of raw

materials and product

• movement and

control of people

• design and

installation of the process equipment

• design and

installation of services

and hygienic practises which include:

• practises that return the processing environment to its original condition. These are usually referred to as cleaning and disinfection or sanitation programmes.

• practices that keep the building and equipment in efficient operation. These are referred to as the maintenance programme.

• practices that relate to the control of cross-contamination during manufacture, usually related to people, surfaces, the air and the segregation of raw and cooked product. Such control is generally referred to as Good Manufacturing Practice (GMP).

Hygienic design and hygienic practices include almost all the listed PRPs. However there are others such as supplier control and recall programmes. These are added.

A food safety management programme (HACCP) is a surround that encompasses all these things.

PRPs listed in SABS 10330

Hygienic Design

- External areas to the facility

- Building structure, ablution facilities, production,distribution and storage facilities

- staff and product flow

- construction of equipment

- services needed for production, for example, air, water

- maintenance programme

- cleaning and disinfection programme

- pest control programme

- refuse and waste control programme

- personal hygiene programme

- product recall and traceability programme

- control of suppliers

- relevant training programmes

- relevant records